Twelve years of qualification

Twelve years of qualification

Audited Supplier

Audited Supplier

In This Store

Category:Preparation Equipment > Preparation Machinery for Solid Medcine > Granulator

Product Name:XL & XYZL ROTATING GRANULATOR for Isatis Root Granules

Price(USD):2500-6500$

Company:Jiangyin Snynxn Granulating Drying Equipment Co., Ltd.

Factory Location: Jiangyin city,Jiangsu,China

Main Sales Markets: North America,Central/South America,Western Europe,Eastern Europe,Australasia,Asia,Middle East,Africa

Monthly Production Capacity: 10

Contract Manufacturing: CMO

Packaging Information: Export wooden box

Delivery Lead Time: 2 months

Sample Provided: no

Payment Terms: T/T

Description of xtruding granulator

Description of xtruding granulator

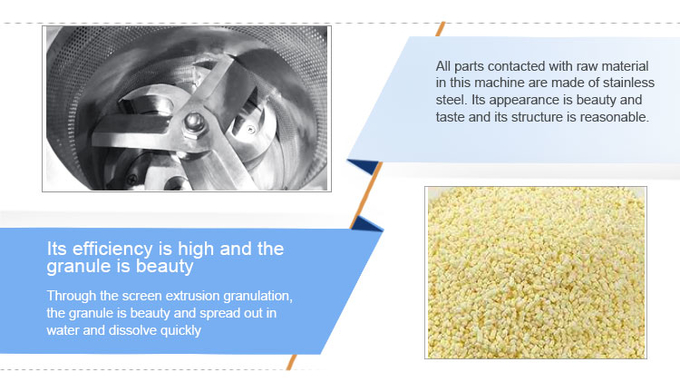

This machine is suitable for making mixed damp material to strip shape granules. It is widely used in pharmaceutical, food, dissolved medicines, chemical and solid drinking industries. The size of granule can be regulated by changing the sieve.

Work principle of extruding granulator

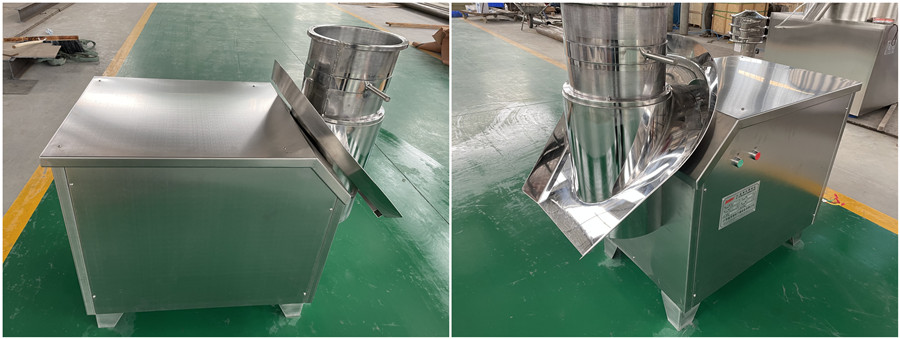

XL rotary extruding granulator is used for wet granulation, which mainly consists of drive motor, feeding hopper, extrusion blades, screen and discharging chute. Wet mass is gravity fed into the granulator and wiped through the perforated screen by extrusion blades to get require-sized cylindrical extrudates. Finished granules are discharged into the barrel via the chute. The gap between blade and screen is adjustable.

XL extruding granulator is most often used in pharmaceutical, food and chemical industries for making granules with wet mass before spheronization.

Features of extruding granulator

1. Press wet mass through perforated screen to get require-sized cylindrical extrudates

2. Wet granulation for food, chemical and pharmaceutical products

3. Capacity: 20-400 kg/h

4. GMP design

5. Different granule size can be achieved by changing perforated screen

6. Robust,simple and compact design requires minimum maintenance;

7. Made by SUS304 or SUS316 and mirror polished to meet GMP pharmaceutic sanitary standards.

8. Uniform granules, higher output, less fines and low noise.

9. Special drive shaft sealing design can 100% make sure contamination free of product.

Descriptions

This machine adopts one pair of rotating grinding blade to grind form damp material into column-shape granule by stainless steel sieve cylinder which is provided for pelletize in next process.

The machine can obtain different size granule by changing the stainless steel sieve

Technical parameters

| 筒直径 Diameter of cylinder (mm) |

筛筒孔径 Diameter of sieve (mm) |

生产能力 Production capacity (kg/h) |

电机功率 Power of motor (kw) |

外型尺寸 Overall dimensions (L×W×H) (mm) |

| 250 | φ0.8-2.5 | 60-200 | 4 | 700×500×1230 |

| 300 | φ0.8-2.5 | 100-400 | 5.5 | 880×630×1230 |

All dates are used foe reference only. According to the condition of material, our factory has the right to change but not notice, pardon!

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

Follow Us:

Pharma Sources Insight JANUARY 2024

Pharma Sources Insight JANUARY 2024