Standard Member

Standard Member

1: USP Class VI certification,

2: Compliant with FDA 21 CFR 177 toxicity certificate,

3: Meeting the production requirements of GMP for biopharmaceuticals,

4: Precise dimensional tolerance control.

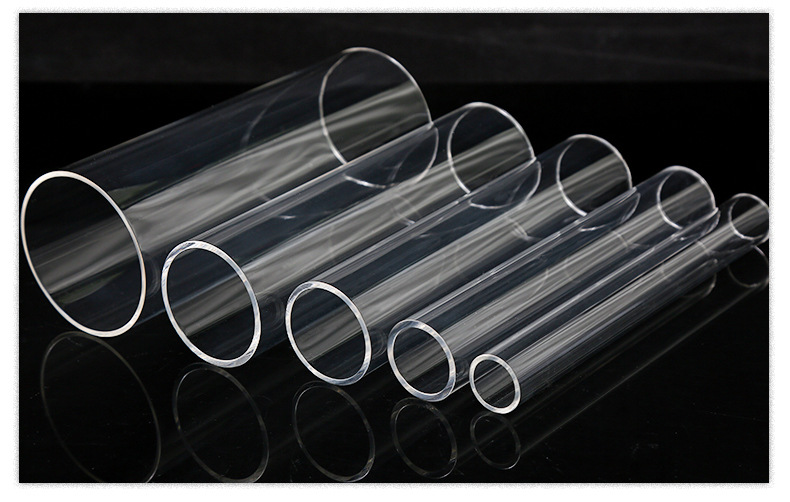

As an easily deformable plastic product, acrylic poses significant production challenges to ensure dimensional tolerance. Products may be scrapped if the tolerance exceeds customer requirements. During production, there can be many issues such as inaccurate dimensions, tapering, elliptical shapes, and poor light transmission,which are actually very difficult to control.

5: High transparency.

|

ID |

ID tolerance(mm) |

Thickness |

Length(mm) |

|

50mm |

±0.015 |

customized |

1000 |

|

60mm |

±0.015 |

customized |

1000 |

|

70mm |

±0.015 |

customized |

1000 |

|

100mm |

±0.02 |

customized |

1000 |

|

120mm |

±0.02 |

customized |

1000 |

|

140mm |

±0.03 |

customized |

1000 |

|

150mm |

±0.03 |

customized |

1000 |

|

200mm |

±0.03 |

customized |

1000 |

|

300mm |

±0.03 |

customized |

1000 |

|

450mm |

±0.1 |

customized |

1000 |

|

630mm |

±0.1 |

customized |

1000 |

|

800mm |

±0.1 |

customized |

1000 |

|

1000mm |

±0.1 |

customized |

1000 |

|

1200mm |

±0.2 |

customized |

1000 |

|

1500mm |

±0.3 |

customized |

1000 |

(All Rights Reserved)

(All Rights Reserved)