Standard Member

Standard Member

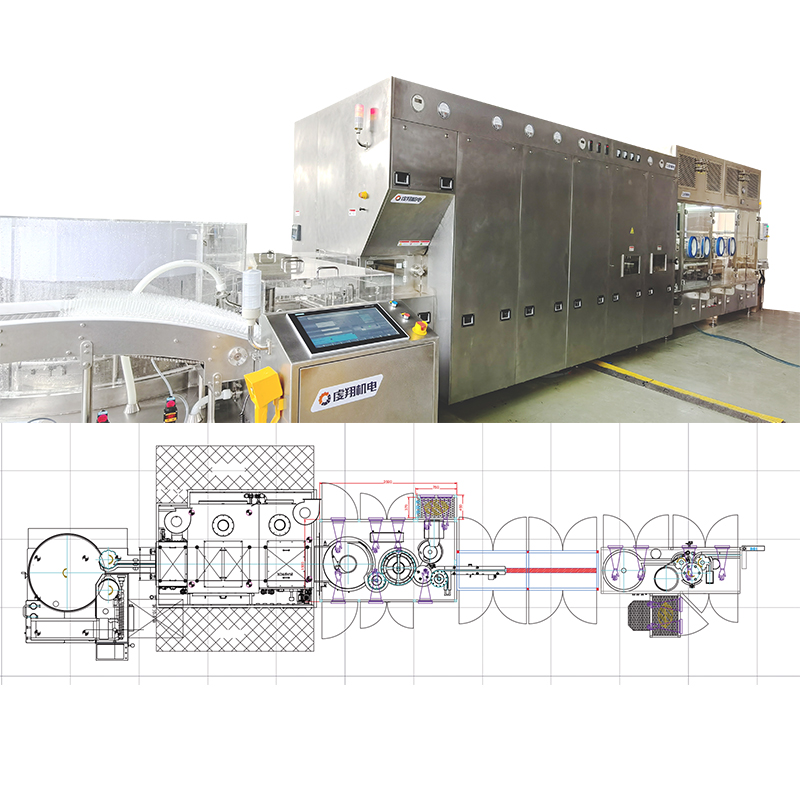

THE EQUIPMENT DESCRIPTION

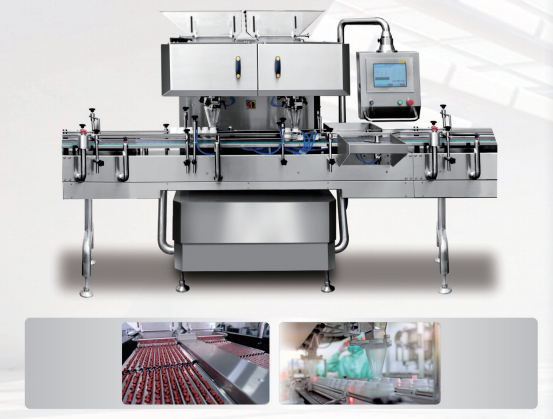

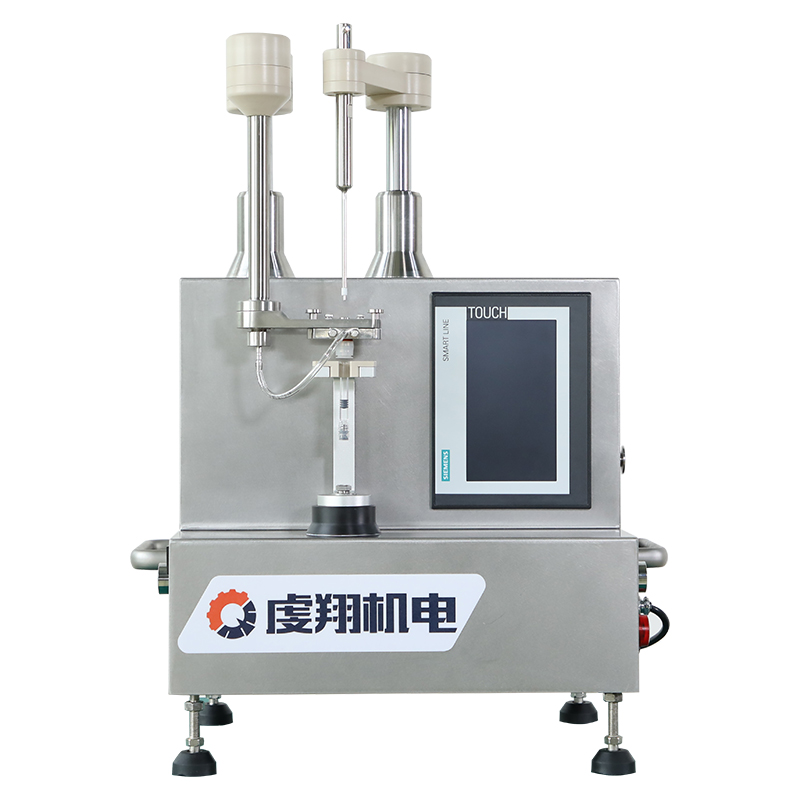

Inside of the monoblock is producing bottling, capping and screwing. Thanks to the rotary disk each bottle alternately goes through all the stages of work:

1. Submission of empty bottles from a loading table and the conveyor belt to the metering device.

2. Dosing filling with a group of reciprocating pumps.

3. Install the plug in the vial. The actuator is a shaker.

4. Putting on the cap with a shaker.

5. Sealed roller shutter, or pre-roll.

6. Unloading ready-made vials to the unloading storage table along a conveyor.

Thanks to the rotary charging table, the vials are placed on the conveyor belt, where they automatically move to the monoblock through the inspection sensor: if the number of bottles is less than a certain number, the candy bar stops. At each stage there are sensors that check the success of the previous stage, in the absence of problems, the bottle moves on.

(All Rights Reserved)

(All Rights Reserved)