Standard Member

Standard Member

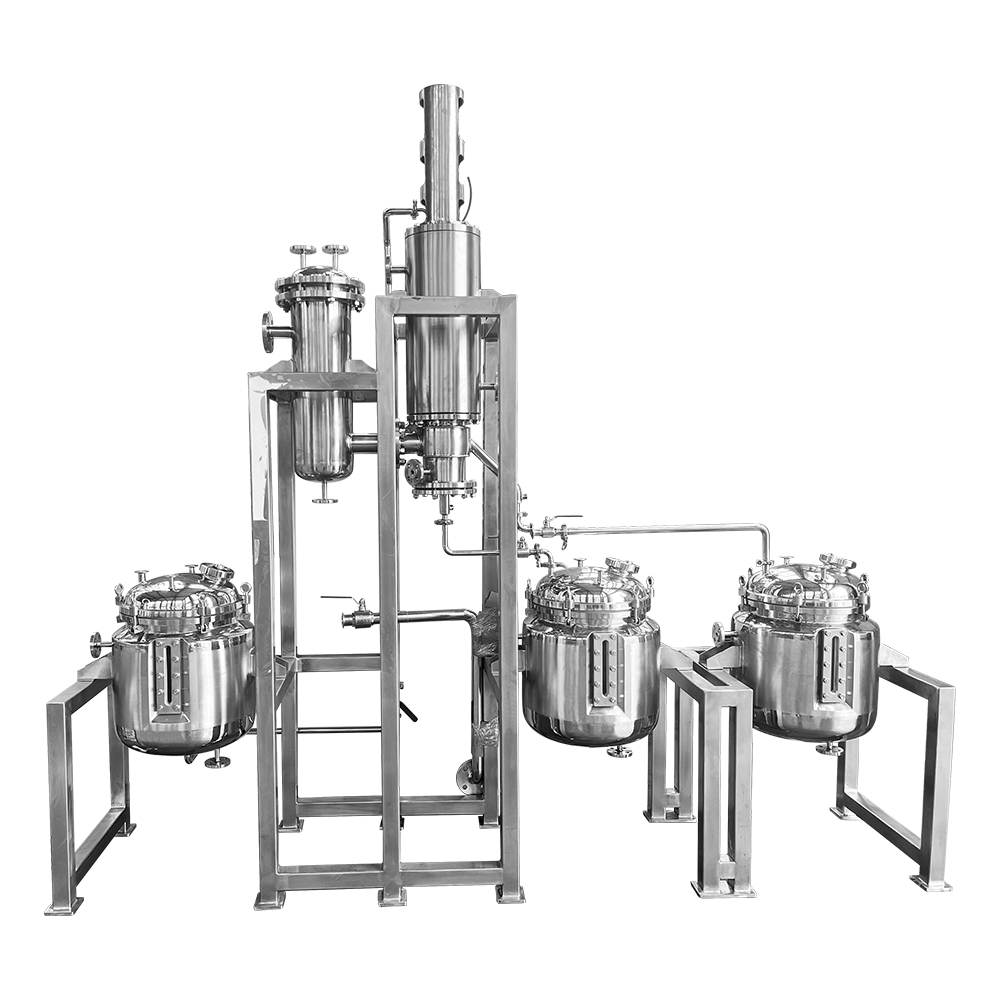

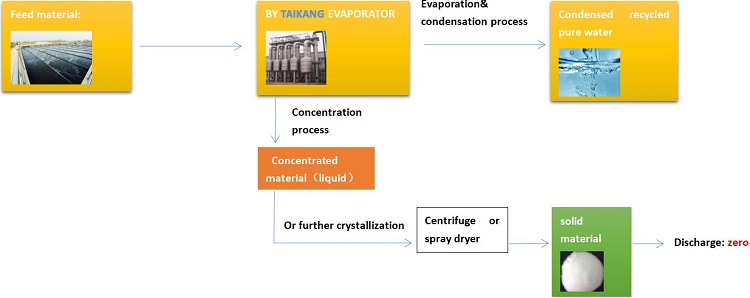

MVR is the abbreviated form of the mechanical vapor re-compression.This is a technology that recovers the energy of the secondary vapor it generates and therefore reduces the demand for external energy.As early as in 1960s,Germany and France have applied this technology successfully to chemical,pharmaceutical,paper-making,waste-water treatment and desalination fields.

When mechanical vapor is re-compressed,the mechanically driven compressor will compress the secondary vapor generated by the evaporator to form a higher pressure.In this sense,the compressor acts as a heat pump to increase energy to the vapor.In another word,in this process,the low-temperature vapor is compressed by the compressor to improve its temperature and pressure and increase its enthalpy and then flow into the heat ex-changer for heat exchange and condensation so as to make use of the latent heat of the secondary vapor.Except machine start-up,no generation of additional vapor is required during the entire evaporation process.

1,Low energy consumption,low operation cost

2,Small space occupation

3,Require fewer public utilities and less total investment

4,Stable operation and high degree of automation

5,Require no primary steam 6,Short retention time due to frequently used single effect

(All Rights Reserved)

(All Rights Reserved)