Standard Member

Standard Member

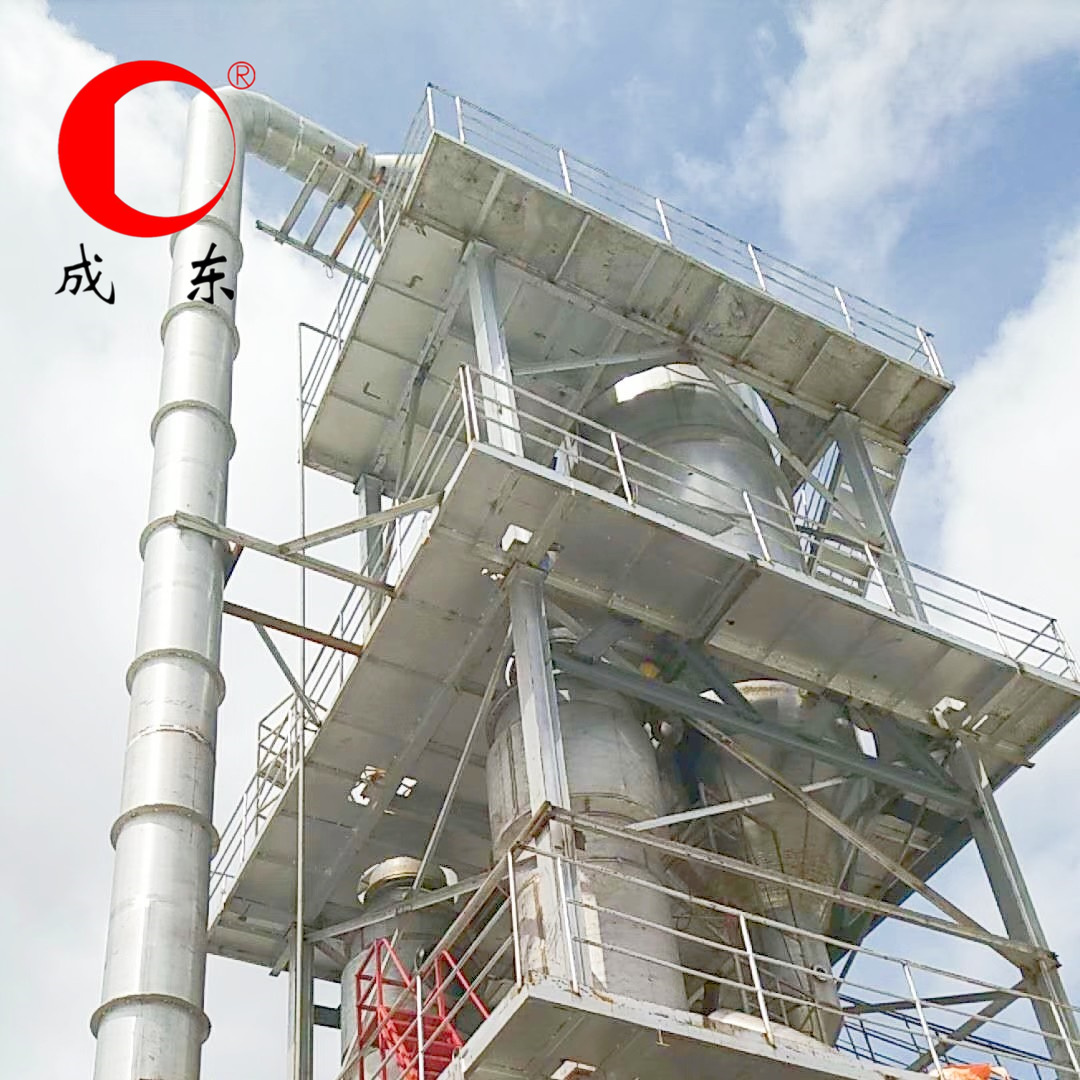

MVR is called Mechanical Vapor Re-compression. It takes use of the compressor to re-compress the second vapour(low temperature and low pressure) which is evaporated from the liquid material to rise its temperature and pressure, so as to reuse it as heating source to evaporate the liquid material again.

During the MVR evaporating process, there is no need to add extra original steam from boiler(or very little steam consumption when the liuquid temperature is too low). All we need to do is to supply electricity for the compressor to recompress the second vapour continuously so as to gain boundless energy source for the evaporation process.

It can be widely used to Milk, glucose, organic acid, VC, xylose, pharmaceutical, plant, chemical industry, environmental protection, waste recycling, paper making, salt making industry such as evaporation and concentration, evaporation crystallizaion, low temperature of evaporation process etc.

(All Rights Reserved)

(All Rights Reserved)