Gold Member

Gold Member

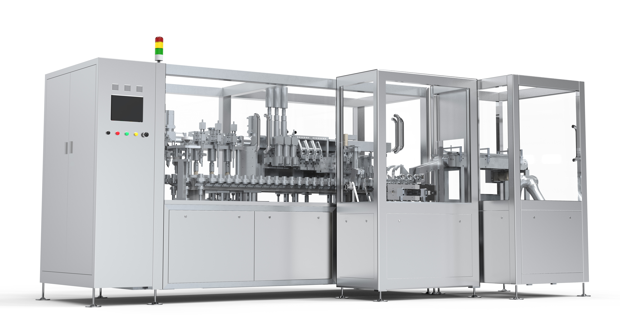

1.Intelligent Control

ØFull Servo Motor Control:The entire machine adopts fully servo motor control, completely eliminating mechanical cams.

ØTouchscreen HMI (Human-Machine Interface): enables on-screen adjustment of filling parameters to accommodate varying paste viscosities, ensuring quick and intuitive setup; features recipe memory function for rapid product changeovers; integrated self-diagnostic system displays fault alerts in real time; provides complete data traceability (compliant with FDA 21 CFR Part 11), includes audit trail (pharmaceutical GMP standard) and supports electronic signature functionality (per ISO 13485 requirements).

2. High Production Efficiency

ØHigh-speed Filling & Sealing: designed capacity: 240 tubes/min; Actual production capacity: 180-200 tubes/min.

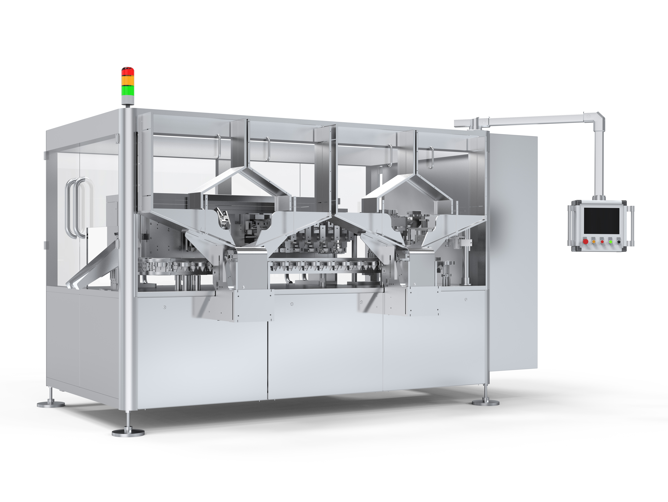

L: Mechanical Folding

N:Hot air sealing

3. Superior Reliability

ØAutomatic Tube Loading: compatible with robotic arm pickup or automatic tube

loader, minimizing manual intervention.

ØUpgraded Sealing Mechanism: optimizing structure enhances sealing stability and reliability.

4. Modular & Flexible Desing

ØStreamlined architecture for easy maintenance; optional stainless steel filling pump or ceramic filling pump ( with rotary valve).

ØIndustry 4.0 Ready: pre-installed communication ports (OPC UA/Modbus) for smart factory integration.

5. Cutting-Edge Design Philosophy

ØWorld’s First Fully Servo-Driven Technology! Represents the pinnacle of mechatronic integration in global filling equipment. Sets new benchmarks for intelligent production in the packaging industry.

(All Rights Reserved)

(All Rights Reserved)