Standard Member

Standard Member

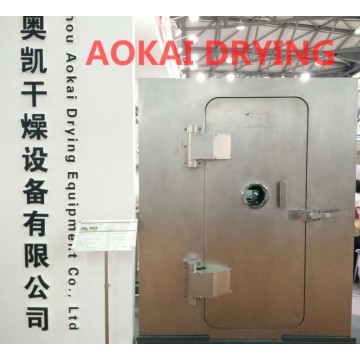

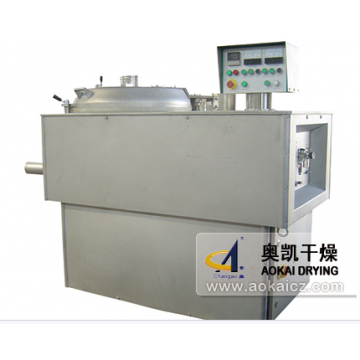

Notes: Consisting of separated oven main body and auxiliary part (heating system, circulation system, filters, connecting air duct and air valves).

Advantages:

1. Suitable for the drying of APIs (Active Pharmaceutical Ingredients) in the synthetic area and refining-drying-packing workshop, and granules in solid preparation workshop.

2. Design and manufacturing according to GMP/cGMP/FDA certification requirements.

3. Clean hot air fully contacted with materials due to forced convection design. Drying efficiency improved; drying time shortened; 2-5 times drying rate than that of ordinary ovens.

4. No need to turn over materials during drying.

5. Separated design for dynamic and static parts. Easy for cleaning the material area.

6. Circulation system equipped with filters.

7. Temp. tolerance within ±2 ºC.

8. Patented product with patent no.: ZL201020125055.2., ZL201420166706.0.

Technical Parameters

| Model | Loading Capacity/Batch (KG) | Installed Power (kW) | Drying Rack (Set) | Drying Tray (Pieces) | Outline Dimension of Main Body (mm) | Outline Dimension of Auxiliary Machine (mm) | Temperature Difference (ºC) |

| CTDE-CF-A | 20-50 | ~5 | 1 | 10 | 1750*1200*1800 | 2000*1500*2400 | +-2 |

| CTDE-CF-I | 60-100 | ~7 | 1 | 20 | 1900*1300*2050 | 2300*1800*2700 | +-2 |

| CTDE-CF-II | 150-200 | ~12.5 | 1 | 30 | 2150*1600*2200 | 2600*2180*3300 | +-2 |

(All Rights Reserved)

(All Rights Reserved)