Standard Member

Standard Member

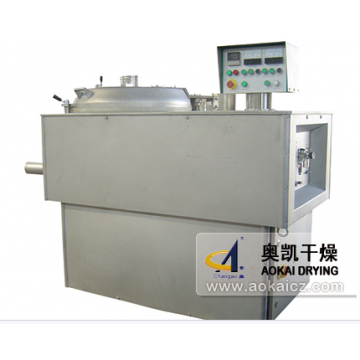

Principle:

The powdery raw material and adhesive in a cylinder are fully mixed at the bottom to become a humid soft material. Then it is cut by high-speed cutter and become uniform damp granules.

Product Feature:

1. The machine adopts horizontal cylinder structure, its structure reasonable.

2. The inner surface of equipment has no dead corner. It works at sealed state and conforms to the requirements of GMP.

3. Granulating time is short, high efficiency and energy saving.

4. The character of granule is uniform and the mobility of granule is good. It provides ideal granule material to tablet pressing procedure.

5. Compared with traditional process, it can reduce 25% of binder and shorten drying time too.

6. Each batch needs 2 minutes to dry mixing and 1~4minutes to granulating. Compared with traditional process, its efficiency can raise 4~5 times.

7. Whole operation has strict safe protective measures.

8. It can mix uniformly even when the gravity difference between main material and accessories is very big, without the layered phenomenon.

| Item | Specification | ||||||||

| Name | Unit | GHL10 | GHL50 | GHL150 | GHL200 | GHL250 | GHL300 | GHL400 | GHL600 |

| Capacity | L | 10 | 50 | 150 | 200 | 250 | 300 | 400 | 600 |

| Output | Kg/batch | 3 | 15 | 50 | 80 | 100 | 130 | 200 | 280 |

| Mixing speed | Rpm | 300/600 | 200/400 | 180/270 | 180/270 | 180/270 | 140/220 | 106/155 | 80/120 |

| Mining power | Kw | 1.5/2.2 | 4/5.5 | 6.5/8 | 9/11 | 9/11 | 13/16 | 18.5/22 | 22/30 |

| Cutting speed | Rpm | 1500/3000 | |||||||

| Cutting power | kw | 0.85/1.1 | 1.3/1.8 | 2.4/3 | 4.5/5.5 | 4.5/5.5 | 4.5/5.5 | 6.5/8 | 9/11 |

(All Rights Reserved)

(All Rights Reserved)