Standard Member

Standard Member

-

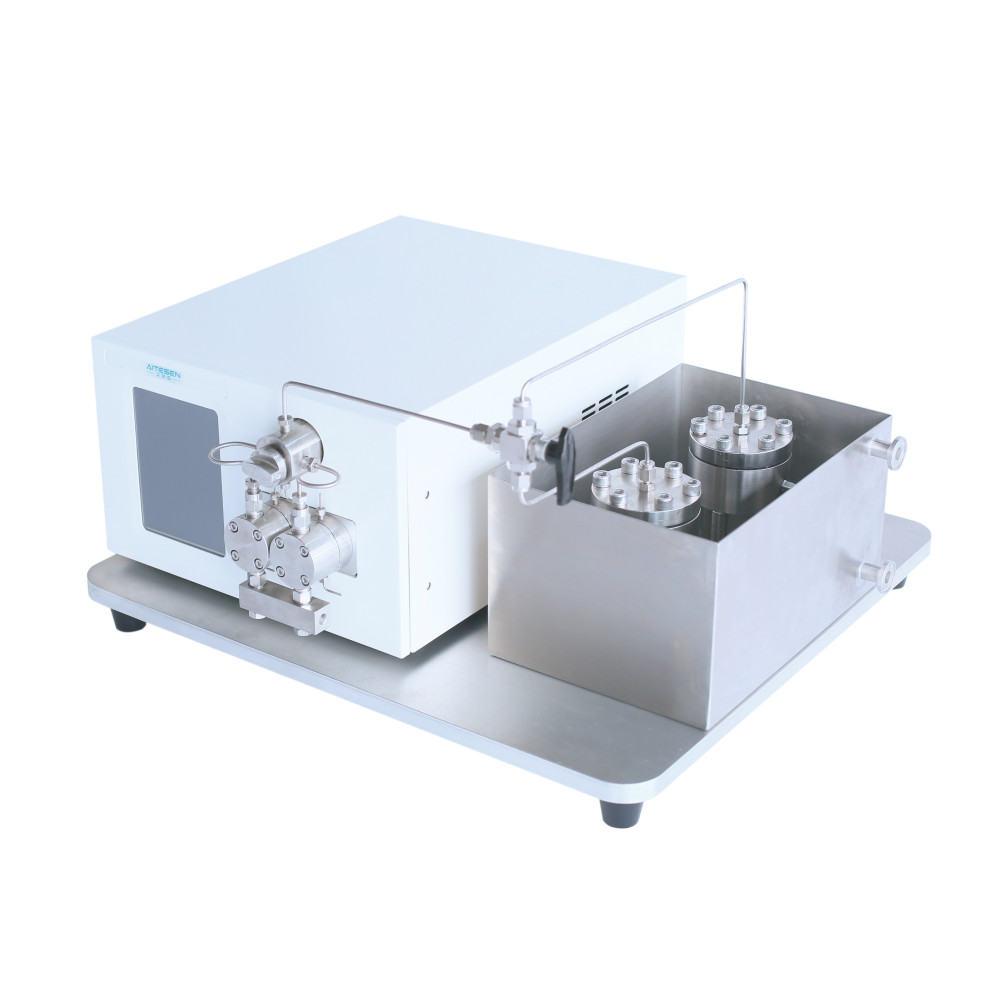

- OLExS SERIES CONTINUOUS LIPOSOME EXTRUSION EQUIPMENT

OLExS Continuous liposome extrudator

PRINCIPLE

The principle of liposome extrusion is that the liposome vesicles are squeezed through a certain extrusion power source, so that they can pass through the PC filter membrane under certain pressure conditions. This pressure, as the shear force in the process of liposome vesicles crossing the membrane, can achieve the effect of particle size control. Its morphology, size, and distribution can be greatly improved.

OLExS continuous liposome extrusion equipment mainly solves the problems of large size and poor stability of materials such as liposome and nanoparticles, and can effectively control the size and distribution of sample particles. OLExS continuous liposome extruder has the characteristics of good effect, high efficiency, convenient use and small footprint, which provides a good operation experience for the development and production of liposome in universities and enterprises.

TECHNICAL PARAMETER:

|

Model |

OLExS-L |

OLExS-PI |

OLExS-Pd |

|

Maximum Pressure[Mpa] |

10 |

10 |

10 |

|

Final Product Size[nm] |

50~1000 |

50~1000 |

50~1000 |

|

Batch Sample Volume |

15~2000mL |

50~3000mL |

3L~500L |

|

Maximum Product Concentration[mg/mL] |

200 |

200 |

200 |

|

Operating Temperature Range[℃] |

5~80 |

5~80 |

5~80 |

|

Material |

SS316L |

SS316L |

SS316L |

|

Power Source |

Piston Pump |

Piston Pump |

Piston Pump/Diaphragm Pump |

|

Extruder Diameter [mm] |

47 |

90/142 |

142/293 |

|

Number of Extruder Unit |

2 |

2 |

≥2 |

|

Maximum Flow Rate |

200mL/min |

600mL/min |

600-1000L/H |

|

Flow Rate Continuously Adjustable |

√ |

√ |

√ |

|

High and Low Voltage Protection |

√ |

√ |

√ |

|

Flow Setting Error |

≤±1% |

≤±1% |

≤±1% |

|

Flow Repeatability Error% |

≤1% |

≤1% |

≤1% |

|

Pressure Pulsation[MPa] |

≤0.2 |

≤0.2 |

≤0.2 |

|

Pressure Accuracy[MPa] |

≤0.1 |

≤0.1 |

≤0.1 |

(All Rights Reserved)

(All Rights Reserved)