March 06, 2025

Tag:

一. Introduction

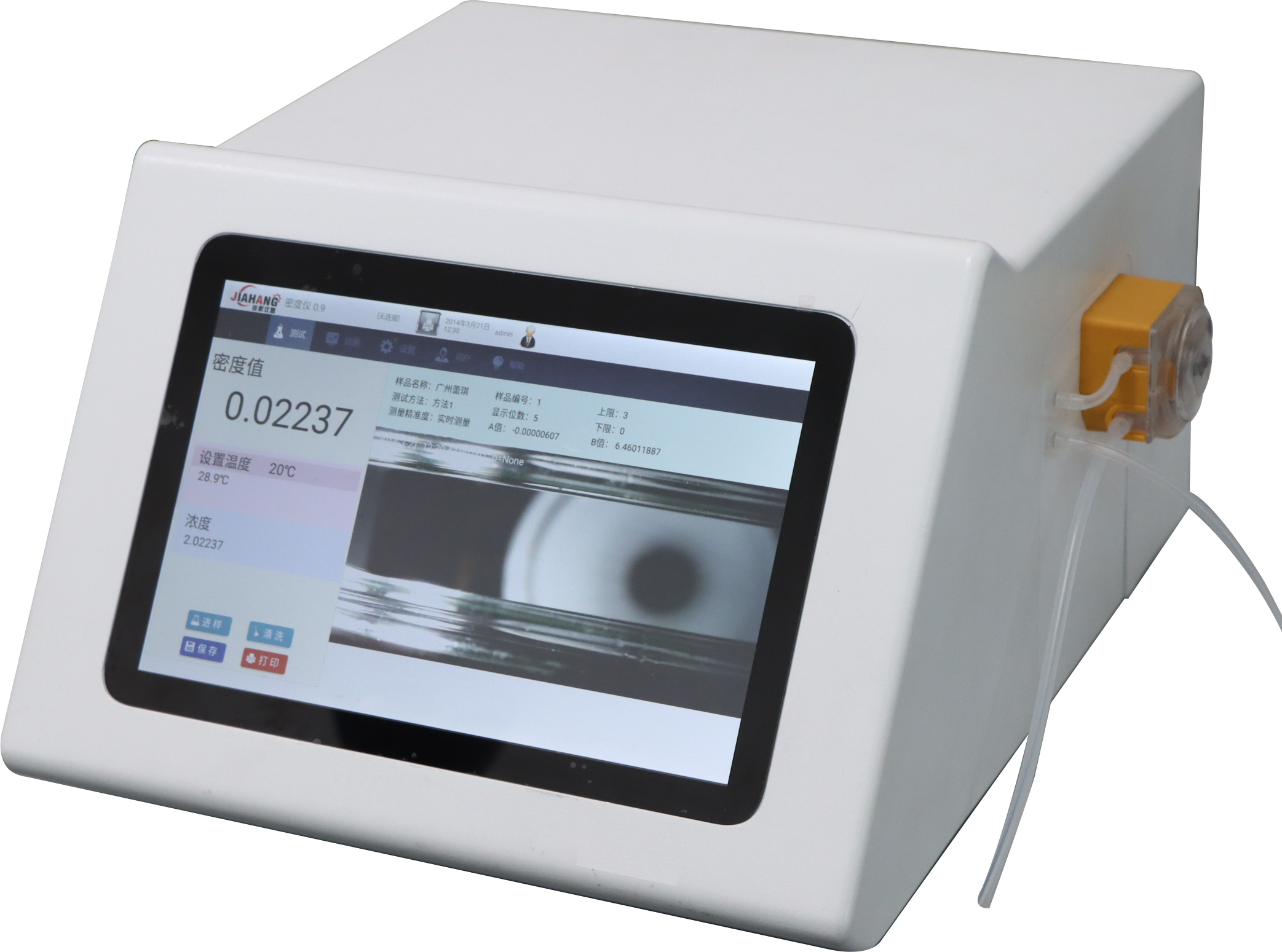

As a synthetic concentrated aromatic oil, essence is widely used in food, daily necessities, cosmetics, cigarettes and many other fields. In the production of flavors and fragrances, density is a key quality indicator, and its accurate detection is crucial to ensure product quality, stability and compliance with relevant standards. The traditional hydrometer method and volumetric bottle method have many drawbacks, such as low detection accuracy, long time, large sample consumption, easy to produce human error, etc., which is difficult to meet the high frequency and large quantity detection needs of modern flavor and fragrance industry. Digipol-D70 automatic densitometer produced by Shanghai Jiahang Instrument Co., LTD., with advanced detection technology and intelligent design, provides an efficient and accurate solution for flavor density detection.

2. Reference standards

1.GB 5009.2-2016 "Determination of relative density of food in National Standard for Food Safety" : specifies the determination method of relative density of food, which is applicable to all kinds of food and provides a standard basis for the detection of flavor density.

2.GB/T 11540-2008 "Determination of the relative density of spices" : a standard specifically formulated for the determination of the relative density of spices to ensure the standardization and accuracy of the density detection of spice products.

3.GB/T 4472-2011 "Determination of Chemical Product density Relative density" : covers the determination requirements of chemical product density and relative density, flavors and spices as fine chemical products, can be tested according to this standard.

4.GB/T 13531.4-2013 "Determination of the relative density of the General Inspection Method for Cosmetics" : to provide operational specifications for the detection of the density of flavors and fragrances in cosmetics to ensure that product quality meets the cosmetic industry standards.

二. Instrument use

1. Startup preheating: turn on the power supply of Digipol-D70 automatic densitometer, and automatically initialize the instrument after startup. Preheat 15-30 minutes, so that the internal parts of the instrument to achieve a stable working state, to ensure the accuracy of the measurement results.

2. Calibration operation: When used for the first time or not used for a long time, calibration is required. Air and distilled water were used as calibration media, and calibration steps were carried out successively according to the instructions on the instrument operation interface. Ensure a stable environment and avoid vibration and airflow interference during calibration.

3. Temperature control adjustment: The instrument has a built-in high-precision temperature control system, which can accurately set the temperature within the range of 15-40 ° C according to the detection requirements. By inputting the target temperature value through the operation interface, the instrument adopts advanced temperature control technology to quickly reach and stabilize the set temperature, and the temperature control accuracy can reach ±0.05℃, effectively eliminating the influence of temperature on the measurement of flavor density.

4. Sampling process: Use a matching sampling tool to absorb 2-3ml samples and slowly inject them into the measuring pool of the instrument. During the sampling process, ensure that the sample is free of bubbles. If there are bubbles, gently tap the measuring pool to discharge the bubbles and avoid bubbles affecting the measurement results.

5. Measurement start: After the sample injection is completed and the temperature is stable, select the appropriate measurement mode on the instrument operation interface and start the measurement procedure. The instrument automatically detects the sample density, the measurement time is short, the single sample measurement only takes about 1 minute, and the accurate measurement data is quickly obtained.

6. Data processing: The measurement results are automatically displayed on the large LCD screen of the instrument, and the instrument has the function of multi-parameter data conversion, which can directly display the density, relative density and other data. Automatic storage of measurement data, up to 1000 sets of storage capacity, convenient access to historical data at any time. Data can be exported through RS232, USB interface, also support U disk storage, can also connect to the printer (optional) directly print measurement report, report format support PDF, Excel, easy data management and analysis.

7. Cleaning and maintenance: After the measurement is completed, use the built-in cleaning function of the instrument to discharge the sample in the measuring pool through the air pump. Then rinse the measuring pool with distilled water and anhydrous alcohol 3-5 times in sequence to ensure that the measuring pool is clean. After cleaning, dry the measuring tank with dry air to prevent residual liquid from affecting the accuracy of the next measurement.

三. Measurement data

The Digipol-D70 automatic densitometer has been proved to be stable and reliable in measuring data of flavor and fragrance samples. Taking a series of flavor as an example, the results of multiple measurements are as follows:

It can be seen from the measurement data that the instrument has high measurement accuracy, good measurement repeatability, small sampling amount and fast measurement speed, which can meet the high requirements of the flavor and fragrance industry for density detection.

四, product characteristics

1. Small sampling amount: only 2-3ml sample is needed for each measurement, which greatly saves precious flavor and fragrance samples and reduces testing costs.

2. Rapid measurement: After the temperature balance, the measurement time of a single sample is about 1 minute, which significantly improves the detection efficiency and ADAPTS to the testing needs of large quantities of samples.

3. Easy to operate: the instrument adopts humanized design, the 7-inch color LCD touch screen operation interface is simple and intuitive, the operation process is simple and easy to understand, no professional and technical personnel can easily get started.

4. Excellent accuracy: density measurement range is 0.00000-3.00000 g/cm³, measurement accuracy can reach ±0.0003g/cm³, measurement resolution is ±0.00001g/cm³, measurement repeatability is ±0.0001g/cm³, to ensure accurate and reliable measurement results.

5. Convenient data management: equipped with a variety of communication interfaces, complete data storage, export and printing functions, support a variety of data formats, convenient data recording, analysis and report generation, to meet the requirements of enterprise quality management system.

6. Precise temperature control: the temperature control range is 15-40 ° C, the temperature control accuracy is ±0.05 ° C, and the temperature control accuracy is ±0.2 ° C, which effectively eliminates the influence of temperature on the measurement results and ensures the consistency and accuracy of measurement in different environments.

五、 Influencing factors

1.Temperature effect: Temperature has an effect on the essence density and the measurement tank geometry. During the measurement process, the temperature should be strictly controlled and kept within the range of ±0.05℃ of the set temperature to ensure the accuracy of the measurement results.

2. Bubble interference: The presence of bubbles in the measurement pool will cause the resonant frequency to change, resulting in a deviation of the measured density value. Be sure that the sample is free of bubbles when sampling, and remove bubbles in time if found.

3. Viscosity restriction: When the viscosity of the essence is too large, it will affect the resonance frequency of the measuring tank, resulting in increased measurement error. For high-viscosity flavors, appropriate dilution or special treatment is required to ensure measurement accuracy.

4. Volatile effect: Some flavors have volatile characteristics, and should be measured as soon as possible after sampling to reduce the impact of sample concentration changes caused by volatilization on the measurement results.

六. Instrument parameters

| item | Parameter details |

| Manufacturer | Shanghai Jiahang Instruments Co., LTD |

| model | Digipol-D70 |

| name | Automatic Densitometer |

| measurement range | .00000 - 3.00000g/cm³ |

| accuracy | ±0.0003g/cm³ |

| resolution | ±0.00001g/cm³ |

| repeatability | ±0.0001g/cm³ |

| resolution | 0.01℃ |

| control range | 15 - 40℃ |

| control accuracy | ±0.2℃ |

| control accuracy | ±0.2℃ |

| Calibration Method | Air/distilled water |

| Data storage | 1000 groups |

| Display mode | 7 inch color LCD touch screen |

| Output interface | RS232, USB, U disk |

| Printer model | selection (support a variety of models) |

| Output report | PDF, Excel |

| Power supply | 220V±20V, 50Hz±1Hz |

| 220V±20V, 50Hz±1Hz | 380mm×450mm×230mm |

| The net weight of the instrument | 23kg |

7. Relevant knowledge (Introduction to relative density volumetric measurement method)

1. Volumetric method to measure relative density steps

1 "Wash liquid, distilled water, ethanol, ether washing volume bottle in turn, after drying and cooling, use a high-precision balance to accurately weigh and record the mass m0.

2) Fill the volumetric bottle with the sample liquid at a temperature below 20 ° C, insert the thermometer, and place it in a 20 ° C water bath for 20 minutes.

3) Use filter paper strip to absorb the spilled liquid, plug the bottle, take out the volume bottle, dry the liquid outside the bottle with filter paper, weigh again and record the mass m1.

4. Wash the volumetric bottle, fill it with distilled water that has been boiled for 30 minutes and cooled to below 20 ° C, repeat the above operation, and record the mass m2.

5) Calculate the relative density according to the formula d20 = (m2-m0)/(m1-m0).

2. Precautions for measuring relative density by capacity method

1. The method is suitable for volatile samples, the measurement results are accurate, but the operation process is complicated, and the operation skills of the experimental personnel are high.

2 "When measuring sticky samples, it is recommended to use ordinary density bottles with capillary tubes to facilitate sample filling and bubble discharge.

3) Ensure that the water and sample are completely filled with the density bottle, and no bubbles remain in the bottle, otherwise it will affect the measurement results.

4) When taking the thermostatic density bottle, wear thermal gloves or use tools to pick up the bottleneck to avoid the hand temperature affecting the temperature and volume of the liquid in the bottle.

5) Keep the water in the water bath clean and free of oil, prevent pollution of the outer wall of the density bottle, affecting the accuracy of weighing.

6 The temperature of the balance room should be controlled at no more than 20 ° C to prevent the liquid from expanding and flowing out due to excessive temperature, resulting in measurement errors.

Viii. Summary

Digipol-D70 automatic densitometer has shown significant advantages in the density detection of flavor and fragrance industry. Its high precision, fast measurement, easy operation and powerful data management function effectively solve the shortcomings of traditional detection methods. By strictly controlling the influencing factors in the measurement process and operating according to relevant standards and specifications, accurate and reliable density detection data can be provided for flavor and fragrance manufacturers, helping enterprises to improve product quality and enhance market competitiveness.

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

+86 15021993094

Follow Us:

Pharma Sources Insight July 2025

Pharma Sources Insight July 2025