March 14, 2025

Tag:

introduction

NO and NO₂ in diesel exhaust are important components of air pollutants. In order to protect the environment, the environmental protection departments of various countries have put forward strict limits on diesel engine nitrogen oxide emissions. SCR (Selective catalytic reduction technology) has significant advantages in the treatment of exhaust emissions of diesel vehicles in China Ⅳ. As the key additive of SCR, the quality of vehicle urea directly affects the exhaust gas purification effect. At present, automotive urea solution is usually composed of 32.5% high-purity urea and 67.5% deionized water, which requires very high urea concentration and water purity. The purpose of this scheme is to use Digipol-R500 automatic refractometer and Digipol-D70 automatic densitometer of Shanghai Jiahang Instrument Co., LTD., to accurately detect the key indicators of vehicle urea and ensure that its quality meets the national standard.

2. Working principle

SCR system of diesel vehicle is mainly composed of urea storage tank, urea pump, metering pump, SCR body and so on. When working, the vehicle urea sprayed from the urea tank will undergo hydrolysis reaction at high temperature (> 160℃) :

((NH₂)₂CO + H₂O = 2NH₃ + CO₂)

The generated ammonia reacts with nitrogen oxides under the action of the catalyst, the specific reaction formula is as follows:

(4NH₃ + 4NO + O₂ = 4N₂ + 6H₂O),

(4NH₃ + 2NO₂ + O₂ = 3N₂ + 6H₂O),

Eventually, harmless nitrogen and water are formed. In this process, the consumption of vehicle urea and diesel is basically proportional, generally 100L diesel consumes about 4L of vehicle urea, but the actual consumption is affected by engine displacement, model, road conditions, weight and other factors. If the vehicle urea is not added in time, it will lead to excessive emissions and be punished, and the driving computer will limit the engine power, so that the vehicle cannot speed up.

3. Detection index

The choice of qualified automotive urea is very important for diesel owners. High-quality automotive urea should be prepared with deionized water and pure urea raw materials, and the urea concentration should be controlled between 31.8%-33.2% to meet the working requirements of the SCR system. The concentration of urea in inferior vehicles is insufficient to effectively purify nitrogen oxides, which will limit engine power. According to the national standard GB 29518-2013 "Diesel engine nitrogen oxide reducing agent urea aqueous solution", the key indicators of automotive urea aqueous solution are as follows:

| Item | Quality index | experimental method |

| Urea content (mass fraction)/% | 31.8-33.2 | Appendix A |

| Density (20° C) /(g/cm ') | 1.0870-1.0930 | SH/T 0604 |

| Refractive index nD | 1.3814-1.3843 | GB-T 614 |

4. Experiment preparation

4.1 Test equipment

1> Shanghai Jiahang Digipol-R500 automatic refractometer

2> Digipol-D70 automatic densitometer

3> High precision balance

4> Beaker

5> volumetric bottles, etc.

The Digipol-R500 fully automatic refractometer can accurately measure the refractive index of urea solution for vehicles, the Digipol-D70 fully automatic densitometer can accurately measure the density of solution, the high-precision balance is used to accurately weigh reagents, and the beaker and volumetric bottle are used for solution preparation.

4.2 Experimental reagents

Urea (analytically pure), CAS No. : 57-13-6, as the main raw material for preparing urea solution for automotive use.

Purified water for diluting urea to ensure the purity of the solution.

4.3 Reference Standards

GB 29518-2013 "Diesel engine nitrogen oxide reducing agent urea solution"

5. Sample refractive index test

5.1 Refractometer test

Turn on Digipol-R500 automatic refractometer power supply, start up and preheat for 15-20 minutes. After the preheating is completed, set the temperature to 20℃ on the instrument operating interface, and the instrument will automatically control the prism temperature to stabilize at this value.

Use a dropper to absorb an appropriate amount of the sample to be measured, slowly drop it onto the prism of the refractometer to ensure that the sample completely covers the prism surface, and then quickly cover the mask to avoid light interference.

Wait 2-3 minutes for the sample to fully balance with the prism surface temperature. Click the measuring button on the instrument to measure, measure 3-5 times continuously, and observe the refractive index value. When the refractive index does not change in the fourth decimal place, record the value at this time.

After the measurement is completed, the sample residue on the surface of the prism is gently wiped with a clean lens wiping paper, and the surface of the prism is carefully cleaned with a solvent such as ethanol, and then rinsed with distilled water and dried with a clean lens wiping paper. Repeat the above steps to perform at least three tests on the parallel sample, taking the average of the three measurements as the refraction of the sample.

5.2 Record the refractive index test results

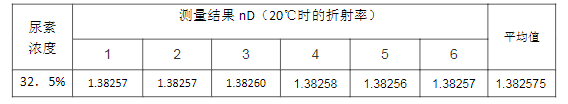

The measurement data can be read directly on the display of the Digipol-R500 automatic refractometer. After the test is completed, the data is recorded in a dedicated table, as shown in the following table (taking urea concentration of 32.5% as an example) :

6. Sample density test

6.1 Density meter Test

Turn on the Digipol-D70 automatic densitometer, and automatically calibrate the internal temperature after the instrument is turned on. Wait about 10-15 minutes until the instrument shows that the temperature is stable, indicating that the internal temperature has been equalized, and the measurement can begin.

When used for the first time or not used for a long time, the instrument needs to be calibrated. Use dry air and distilled water to calibrate in sequence as instructed in the instrument operating manual to ensure measurement accuracy.

The instrument adopts advanced temperature control technology, which can automatically stabilize the measured ambient temperature at 20℃. If the temperature is different, you can fine-tune it on the operation interface.

Use a syringe to absorb 2-3ml of the sample to be measured and slowly inject it into the U-shaped quartz glass tube equipped with the instrument to avoid bubbles. If there are bubbles, gently tap the glass tube to release the bubbles.

Put the U-shaped quartz glass tube containing the sample into the measuring tank of the instrument and wait for 1-2 minutes to make the sample temperature completely balance with the ambient temperature measured by the instrument. Select the appropriate measurement mode on the instrument operation interface and start the measurement.

After the measurement is completed, the instrument automatically converts the measurement results into density values and stores them in the internal memory. The measurement results can be directly viewed through the instrument display, or the data can be exported through the U disk to facilitate subsequent analysis and processing.

After the measurement, use the air pump with the instrument to discharge the sample in the U-tube, and then rinse the U-tube with distilled water and anhydrous alcohol for 3-5 times to ensure that there is no residual sample in the tube. Finally, dry the U-tube with dry air for the next use.

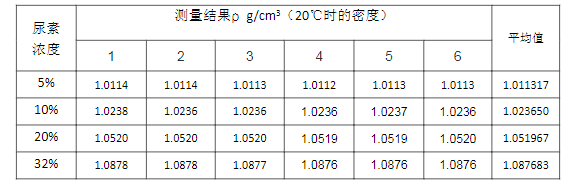

6.2 Record densitometer test results

Record the density measurement results of samples with different urea concentrations in a table as shown below (some sample data) :

7. Discuss

Diesel drivers should not use fertilizer urea mixed with water to make vehicle urea, this homemade urea is low in purity, not only can not effectively purify exhaust gas, but also may damage the vehicle purification system components, pollute the catalyst, and cause combustion system failure. Although the national standard stipulates the use of Dumas nitrogen determination method to measure urea content, in the actual test, because the urea aqueous solution for vehicles is an aqueous solution of pure substances, the urea concentration measured by the Digipol-D70 automatic densitometer can be used as a rapid detection method to provide a reference for detection personnel. In practical application, it should be combined with the measurement results of refractive index and density to comprehensively judge whether the quality of vehicle urea meets the national standard, ensure the normal operation of diesel vehicle SCR system, and reduce the pollution of exhaust gas to the environment.

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

+86 15021993094

Follow Us:

Pharma Sources Insight July 2025

Pharma Sources Insight July 2025