March 18, 2025

Tag:

I. Introduction

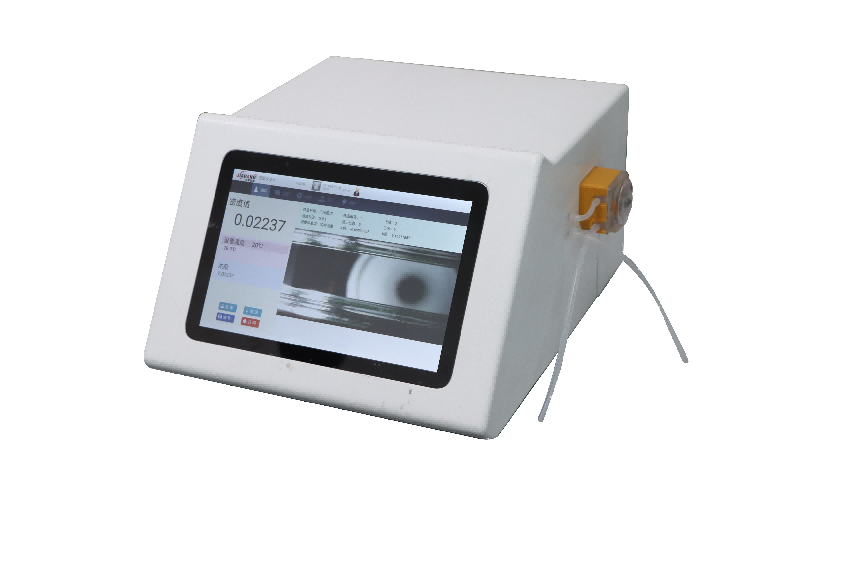

As an important chemical raw material, ammonia is widely used in many industries. The accurate detection of its concentration is very important for ensuring production safety, improving product quality and controlling production cost. The fully automatic density meter Digipol-D70 from Shanghai Jiahang provides an efficient and accurate solution for ammonia concentration detection.

Second, the nature and use of ammonia water

(1) Physical properties

Ammonia is colorless, transparent and has a strong pungent odor liquid, soluble in water and ethanol. The ammonia content of industrial ammonia is usually between 25% and 28 wt%, up to 35 wt%, and the higher the ammonia content, the less dense it is. It belongs to the class 8.2 alkaline corrosion products, with strong corrosion, easy decomposition of ammonia, decomposition speed up when heated, in the case of open fire, heat source may form an explosive atmosphere, while the human eye, nose, skin is irritating and corrosive, so it needs to be sealed in brown reagent bottle, placed in a cold dark place.

(2) Purposes

Ammonia is widely used in industrial fields, involving power plants, cement plant flue gas desulfurization, pharmaceutical, textile, printing and dyeing, silk production and other industries, in agricultural fertilization, medical disinfection, chemical synthesis, oil field exploitation, coal water slurry preparation, building materials processing, food processing, paper and other links also play an important role.

Iii. Comparison of ammonia concentration detection methods

Although the traditional hydrochloric acid titration and sulfuric acid titration can accurately determine the concentration of ammonia, the operation process is complicated, requires the use of a variety of chemical reagents, and the titration process is easily affected by human factors. The industrial density-specific gravity method is used to measure the density of ammonia water through a densitometer, and then obtain the concentration according to the manual. The operation is relatively simple, but the accuracy is limited, and it is only suitable for preliminary detection. The fully automatic density meter Digipol-D70 combines advanced technology to directly measure ammonia concentration quickly and accurately, greatly improving the detection efficiency and accuracy.

Fourth, Digipol-D70 automatic density meter application

(1) Instrument characteristics

High precision measurement: The instrument uses advanced sensing technology and precision temperature control system to ensure that the temperature can be accurately controlled during the measurement process, effectively reducing the impact of temperature on the measurement results. The density measurement accuracy can reach [specific accuracy value], the resolution is as high as [specific resolution value], and the density of different concentrations of ammonia can be accurately measured, and then the ammonia concentration can be accurately obtained, providing reliable data support for the production process.

Easy to operate: The instrument is equipped with an intuitive operating interface, and the operator only needs to perform simple operations according to the prompts to complete the measurement. For example, after preheating the machine, calibrating with a standard substance, and then injecting an appropriate amount of ammonia into the instrument through a special sampling device, the measurement mode is selected, and the instrument can quickly complete the measurement and display the results without complicated conversion and table lookup processes.

Fast measurement: Fast measurement speed is a major advantage of Digipol-D70. After the sample temperature balance, a single measurement only needs [specific measurement time], which greatly improves the detection efficiency and meets the demand for rapid detection of a large number of samples in industrial production, especially for real-time monitoring on the production line.

Multi-function and data processing: In addition to measuring the concentration of ammonia, it also has a variety of measurement modes, which can measure various parameters such as density and specific gravity. The built-in data storage function of the instrument can store the measurement data [specific number of storage groups] and support a variety of data output methods, such as exporting the data to the computer through RS232 and USB interfaces, which is convenient for subsequent data processing and analysis, and can also be connected to the printer to directly print the measurement report.

Low sample consumption: Measuring a sample only requires [specific sample amount] ammonia water, which saves samples and reduces the contact time between operators and ammonia water, reduces operational risks, and ensures personnel safety.

(2) Operation process

Boot preheating: After turning on the power supply, turn on the instrument switch, wait for the internal temperature of the instrument to reach a stable state, the general preheating time is [specific preheating time].

Calibrate the instrument: Calibrate the instrument using standard calibration substances such as dry air and distilled water to ensure the accuracy of the measurement results. According to the prompts on the instrument operation interface, the calibration operation is carried out in turn. After the calibration is completed, the instrument automatically records the calibration data.

Sample preparation: Shake the ammonia sample to be tested well to ensure that the sample is uniform. Use a special syringe or sampling device to absorb an appropriate amount of sample (about [specific sampling amount]), taking care to avoid bubbles in the sample.

Measurement process: Connect the sample feeding device with the instrument, select the "ammonia concentration measurement" mode, and start the measurement procedure. The instrument automatically measures the sample and displays the temperature, density and other parameters of the sample in real time during the measurement process.

Data processing and result recording: After the measurement is completed, the instrument automatically calculates and displays the ammonia concentration. The operator can view the measurement results and store the data inside the instrument or export it to external devices. If further analysis of the measurement results is required, the data can be imported into the computer and processed using professional data processing software.

Cleaning and maintenance: After the measurement is completed, the sampling system of the instrument is cleaned with distilled water and anhydrous alcohol in time to ensure that there are no residual samples inside the instrument. Regular comprehensive maintenance of the instrument, check the performance indicators of the instrument, to ensure that the instrument is always in good working condition.

(3) Examples of measurement data

By measuring the standard solution of ammonia water with different concentrations, the following data are obtained (the measurement temperature is [specific measurement temperature]) :

Second, the nature and use of ammonia water

(1) Physical properties

Ammonia is colorless, transparent and has a strong pungent odor liquid, soluble in water and ethanol. The ammonia content of industrial ammonia is usually between 25% and 28 wt%, up to 35 wt%, and the higher the ammonia content, the less dense it is. It belongs to the class 8.2 alkaline corrosion products, with strong corrosion, easy decomposition of ammonia, decomposition speed up when heated, in the case of open fire, heat source may form an explosive atmosphere, while the human eye, nose, skin is irritating and corrosive, so it needs to be sealed in brown reagent bottle, placed in a cold dark place.

(2) Purposes

Ammonia is widely used in industrial fields, involving power plants, cement plant flue gas desulfurization, pharmaceutical, textile, printing and dyeing, silk production and other industries, in agricultural fertilization, medical disinfection, chemical synthesis, oil field exploitation, coal water slurry preparation, building materials processing, food processing, paper and other links also play an important role.

Iii. Comparison of ammonia concentration detection methods

Although the traditional hydrochloric acid titration and sulfuric acid titration can accurately determine the concentration of ammonia, the operation process is complicated, requires the use of a variety of chemical reagents, and the titration process is easily affected by human factors. The industrial density-specific gravity method is used to measure the density of ammonia water through a densitometer, and then obtain the concentration according to the manual. The operation is relatively simple, but the accuracy is limited, and it is only suitable for preliminary detection. The fully automatic density meter Digipol-D70 combines advanced technology to directly measure ammonia concentration quickly and accurately, greatly improving the detection efficiency and accuracy.

Fourth, Digipol-D70 automatic density meter application

(1) Instrument characteristics

High precision measurement: The instrument uses advanced sensing technology and precision temperature control system to ensure that the temperature can be accurately controlled during the measurement process, effectively reducing the impact of temperature on the measurement results. The density measurement accuracy can reach [specific accuracy value], the resolution is as high as [specific resolution value], and the density of different concentrations of ammonia can be accurately measured, and then the ammonia concentration can be accurately obtained, providing reliable data support for the production process.

Easy to operate: The instrument is equipped with an intuitive operating interface, and the operator only needs to perform simple operations according to the prompts to complete the measurement. For example, after preheating the machine, calibrating with a standard substance, and then injecting an appropriate amount of ammonia into the instrument through a special sampling device, the measurement mode is selected, and the instrument can quickly complete the measurement and display the results without complicated conversion and table lookup processes.

Fast measurement: Fast measurement speed is a major advantage of Digipol-D70. After the sample temperature balance, a single measurement only needs [specific measurement time], which greatly improves the detection efficiency and meets the demand for rapid detection of a large number of samples in industrial production, especially for real-time monitoring on the production line.

Multi-function and data processing: In addition to measuring the concentration of ammonia, it also has a variety of measurement modes, which can measure various parameters such as density and specific gravity. The built-in data storage function of the instrument can store the measurement data [specific number of storage groups] and support a variety of data output methods, such as exporting the data to the computer through RS232 and USB interfaces, which is convenient for subsequent data processing and analysis, and can also be connected to the printer to directly print the measurement report.

Low sample consumption: Measuring a sample only requires [specific sample amount] ammonia water, which saves samples and reduces the contact time between operators and ammonia water, reduces operational risks, and ensures personnel safety.

(2) Operation process

Boot preheating: After turning on the power supply, turn on the instrument switch, wait for the internal temperature of the instrument to reach a stable state, the general preheating time is [specific preheating time].

Calibrate the instrument: Calibrate the instrument using standard calibration substances such as dry air and distilled water to ensure the accuracy of the measurement results. According to the prompts on the instrument operation interface, the calibration operation is carried out in turn. After the calibration is completed, the instrument automatically records the calibration data.

Sample preparation: Shake the ammonia sample to be tested well to ensure that the sample is uniform. Use a special syringe or sampling device to absorb an appropriate amount of sample (about [specific sampling amount]), taking care to avoid bubbles in the sample.

Measurement process: Connect the sample feeding device with the instrument, select the "ammonia concentration measurement" mode, and start the measurement procedure. The instrument automatically measures the sample and displays the temperature, density and other parameters of the sample in real time during the measurement process.

Data processing and result recording: After the measurement is completed, the instrument automatically calculates and displays the ammonia concentration. The operator can view the measurement results and store the data inside the instrument or export it to external devices. If further analysis of the measurement results is required, the data can be imported into the computer and processed using professional data processing software.

Cleaning and maintenance: After the measurement is completed, the sampling system of the instrument is cleaned with distilled water and anhydrous alcohol in time to ensure that there are no residual samples inside the instrument. Regular comprehensive maintenance of the instrument, check the performance indicators of the instrument, to ensure that the instrument is always in good working condition.

(3) Examples of measurement data

By measuring the standard solution of ammonia water with different concentrations, the following data are obtained (the measurement temperature is [specific measurement temperature]) :

(Note: Due to the volatile nature of ammonia, the concentration will change during each configuration. In general, the higher the concentration of ammonia, the more accurate the measurement. Relative error =(measured value - agreed truth value)/ agreed truth value ×100%)

5. Application Cases

Digipol-D70 automatic density meter plays an important role in the ammonia desulfurization process of a large cement plant. Cement plant uses ammonia desulphurization process to remove SO₂ in flue gas. In the whole desulphurization process, the accurate control of ammonia concentration is directly related to desulphurization efficiency and production cost. In the past, due to the slow detection speed and low precision, the concentration of ammonia can not be adjusted in time, resulting in unstable desulfurization effect and a certain waste of resources. After the introduction of Digipol-D70 automatic density meter, the ammonia concentration can be monitored in real time, and the amount of ammonia added can be adjusted in time according to the measurement results, which improves the desulfurization efficiency [specific percentage increase], and reduces the consumption of ammonia water, saving a lot of costs for enterprises every year.

6. Factors affecting measurement and solutions

(1) Temperature influence

Temperature has a significant effect on ammonia density, which will lead to deviation of measurement results. Digipol-D70 is equipped with a high precision temperature control system, the temperature control accuracy can reach [specific temperature control accuracy value], which can effectively reduce the impact of temperature on the measurement results. Before measuring, ensure that the temperature of the instrument is stable at the set value, and try to ensure that the sample temperature is consistent with the temperature measured by the instrument.

(2) The effect of bubbles

If the sample contains bubbles, the measured density value will be too small, affecting the accuracy of the measurement results. During the sampling process, bubbles should be avoided from the sample. For example, when sampling with a syringe, the sample should be drawn slowly to discharge the air in the syringe. If bubbles are found in the sample, the sample container can be gently tapped to remove the bubbles before measurement.

(3) Viscosity influence

The viscosity of ammonia may affect the measurement accuracy of the instrument. For samples with too high viscosity, it can be measured after appropriate dilution, but it should be noted that the influence of dilution times should be considered when calculating the concentration.

(4) Time impact

Due to the volatile nature of ammonia, the exposure time of the sample to the air should be minimized during the measurement process. After sampling, the measurement procedure should be started quickly to ensure that the measurement is completed in the shortest time to reduce the impact of concentration changes due to volatilization on the measurement results.

Vii. Summary

Digipol-D70, a full-automatic density meter from Shanghai Jiahang, has significant advantages in ammonia concentration detection. Its high precision, rapid measurement, easy operation and multi-functional data processing capabilities provide a reliable means of detection for many industries involving the use of ammonia. Through reasonable operation and effective quality control measures, the performance of the instrument can be fully used to accurately detect the ammonia concentration, ensure the safe and stable operation of the production process, improve production efficiency and product quality, and have broad application prospects.

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

+86 15021993094

Follow Us:

Pharma Sources Insight July 2025

Pharma Sources Insight July 2025