March 18, 2025

Tag:

I. Introduction

The concentration of ethanol in wine is one of the key indexes to measure the quality of wine. The accurate determination of ethanol concentration is of great significance for wine production, quality control and market supervision. With its advanced technology and excellent performance, Shanghai Jiahang's automatic density meter provides an efficient and accurate solution for the determination of ethanol concentration in wine.

2. Reference standards

In the process of ethanol concentration determination in wine, the relevant national standards are strictly followed.

For example, GB5009.225-2016 "Determination of Ethanol Concentration in Wine",

GB/T 10345-2007 "Liquor Analysis",

GB/T 15038-2006 "General Analytical Methods for Wine and Fruit Wine"

GB/T 4928-2008 "Beer Analysis Method"

These standards provide a strong guarantee for the standardization of the assay method and the accuracy of the results.

3. Experimental principles

The content of ethanol in alcohol products is usually expressed as a volume fraction, that is, the number of milliliters of alcohol (% vol) contained in 100ml of alcohol at 20 ° C. When the automatic density meter is used to determine the concentration of ethanol in wine, all kinds of wine samples (such as white wine, wine, rice wine, fruit wine, beer, rum, etc.) are directly heated and distilled, and the distilled liquid is restored to the original volume with pure water. Based on the characteristics of different concentrations of ethanol solutions with different densities, the automatic densimeter accurately measures the density of the distillate, and converts it into a percentage of alcohol volume according to the built-in algorithm, so as to obtain the alcohol volume fraction of the 20℃ sample, that is, alcohol content (% vol). The method is easy to operate and fast to detect, and has been widely used in alcohol industry to detect ethanol concentration.

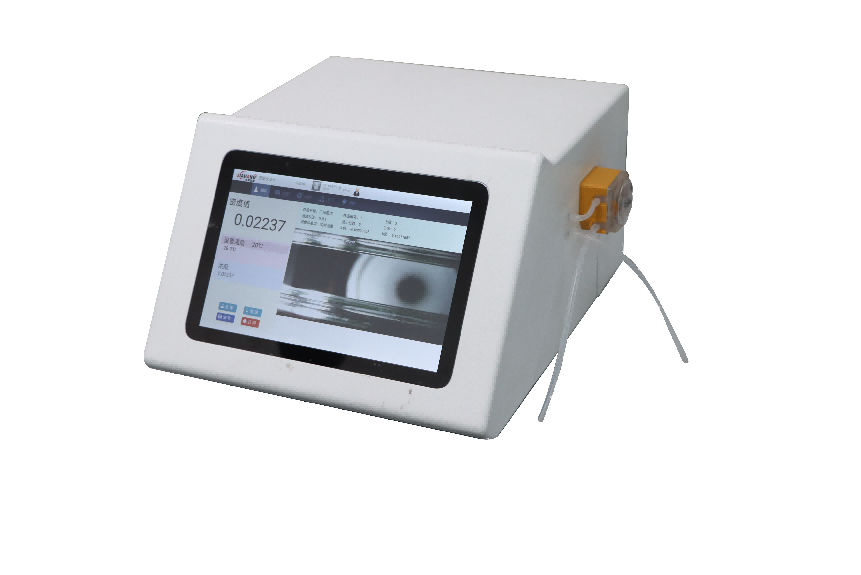

Four, recommended measuring instrument - Shanghai Jiahang automatic density meter

Shanghai Jiahang's fully automatic density meter, with a range of advanced features and advantages, is specially designed for the determination of alcohol ethanol concentration. It uses high-precision sensors and advanced temperature control technology to ensure the accuracy and stability of the measurement process. At the same time, the instrument operation interface is simple and intuitive, easy to use, which greatly improves the detection efficiency.

5. Experimental steps

(1) Sample pretreatment (alcohol distillation)

At room temperature, the 100ml sample is accurately measured using a volumetric bottle and carefully transferred into a 500ml distillation bottle. Then, the volume bottle is washed with the right amount of water, and the cleaning solution is transferred to the distillation bottle to ensure that the sample is not lost. Install the condensate pipe and run cold water into it for cooling. Prepare a 100ml volumetric bottle for receiving distillate. When heating the distillation bottle, it is necessary to strictly control the firepower to avoid excessive firepower, especially in the beginning of the distillation stage. Stop distillation when the volume of collected distillate is close to 95ml. Put the distillate in a water bath and cool it to about 20℃, then fill it with water to 100ml, and shake well for use.

(2) Measurement process

Boot preheating: turn on the automatic density instrument power source and turn on the instrument. The process of waiting for the temperature inside the instrument to reach a stable equilibrium state ensures the accuracy and stability of the instrument measurement.

Calibrating the instrument: When turning on the instrument for the first time or using it regularly, it is recommended to calibrate the instrument with a standard gas (such as dry air) and distilled water. Calibrate the instrument according to the instrument operating guide to achieve the best measurement accuracy of the instrument. The calibration process is a key step in ensuring reliable measurement results.

Sampling operation: Use a matching syringe to absorb 2-3ml of the treated sample and slowly inject it into the measuring chamber of the instrument (such as U-shaped quartz glass tube) to ensure that no bubbles exist in the sample. The presence of bubbles can interfere with measurement results and lead to data bias, so extra care is needed when sampling.

Measurement start: After the sample temperature reaches a balance with the internal temperature of the instrument, select the ethanol concentration measurement mode in the instrument operating interface and start the measurement procedure. The instrument will quickly and automatically measure and analyze the sample.

Data processing: After the measurement is completed, the multi-parameter data conversion system inside the instrument will process the measurement data, directly obtain the ethanol concentration result, and automatically save the measurement data. Through various communication interfaces (such as RS232, USB, etc.) equipped with the instrument, data can be exported to external storage devices (such as U disk), which is convenient for subsequent data collate, analysis, and report printing.

Cleaning and maintenance: After each measurement, the sample in the measuring chamber is discharged with an air pump, and then the measuring chamber is cleaned with distilled water and anhydrous alcohol in turn to remove the residual sample. After cleaning, dry the measuring chamber with dry air to prevent residual liquid from affecting the next measurement and extend the service life of the instrument.

6. Experimental results

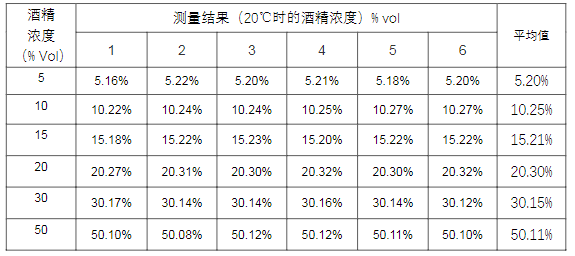

Liquor samples with different ethanol concentrations were measured several times, and the test results were accurate to 0.01% vol. Here are some examples of measurement data:

The measurement error can be effectively reduced and the reliability of the measurement results can be ensured by averaging multiple measurements.

7. Instrument characteristics

(1) The sampling amount is small and the operation is safe

Measuring a single sample requires only 2-3ml of wine sample, which greatly saves the sample amount. At the same time, the amount of contact between the operator and the sample is reduced, which reduces the potential safety risks, especially for the detection of some precious or special wine samples.

(2) Short measurement time and high efficiency

After the sample temperature is balanced, measuring a sample takes only about 1 minute, and the measurement results can be obtained quickly. This efficient measurement speed can meet the needs of wine production enterprises for rapid detection of a large number of samples in the production process, and improve production efficiency.

(3) Direct measurement to reduce errors

The instrument can directly measure the alcohol concentration (standard density) without complicated conversion and table lookup process, avoiding human error caused by conversion and table lookup, and significantly improving the accuracy of measurement.

(4) Easy to operate, suitable for batch testing

The instrument operation interface design is simple and intuitive, and the operator can master the operation method after simple training. Its highly automated measurement process makes it very suitable for high-frequency, high-volume wine sample inspection work, and effectively improves the overall efficiency of detection work.

(5) Data processing is convenient and the results are reliable

The instrument is equipped with a variety of communication interfaces to facilitate data saving, exporting and printing. Measurement results are automatically stored inside the instrument and can be exported at any time for data analysis and report generation. At the same time, the high-precision measurement system ensures the accuracy and reliability of the measurement results, and provides powerful data support for the wine production enterprises and quality supervision departments.

8. Influencing factors

(1) Temperature influence

Temperature has a significant effect on the density of the wine sample, and also changes the geometry of the measurement cavity (such as the U-tube), thus affecting the accuracy of the measurement results. Shanghai Jiahang automatic density meter is equipped with a high-precision temperature control system, which can accurately control the measurement temperature and minimize the impact of temperature fluctuations on the measurement results. During the measurement process, it is important to ensure that the instrument and sample are in the specified temperature environment.

(2) The effect of bubbles

If the sample injected into the measurement cavity contains bubbles, the resonance frequency will increase during measurement, and the measured density value will be small, so that the measurement results of ethanol concentration will be biased. During the sampling process, it should be carried out in strict accordance with the operating specifications to avoid the sample to produce bubbles. Once bubbles are found in the sample, appropriate measures should be taken to remove the bubbles before measurement.

(3) Viscosity influence

The viscosity of the wine sample will affect the resonance frequency of the measurement chamber, and when the viscosity is too high, it may cause the accurate measurement of the ethanol concentration. For wine samples with high viscosity, appropriate dilution treatment can be carried out according to the actual situation, but the influence of dilution ratio should be considered when calculating the ethanol concentration.

(4) Time impact

Some wine samples are volatile. If the time from injection to measurement is too long, the ethanol in the sample may evaporate, resulting in low measurement results. Therefore, after sampling, the measurement procedure should be started as soon as possible to ensure that the measurement is completed in the shortest time to reduce the impact of volatilization on the measurement results.

Ix. Summary

Shanghai Jiahang's fully automatic density meter has demonstrated significant advantages in the determination of ethanol concentration in alcohol. It is not only easy to operate, fast and accurate to measure, but also can effectively deal with many factors that affect the measurement results. It provides a reliable means for alcohol industry to detect ethanol concentration. Whether it is the quality control of wine production enterprises in the production process or the quality inspection of wine products in the market by the quality supervision department, the instrument can play an important role and effectively promote the healthy development of the wine industry.

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

+86 15021993094

Follow Us:

Pharma Sources Insight July 2025

Pharma Sources Insight July 2025