March 18, 2025

Tag:

I. Introduction

In the beer brewing industry, the original wort concentration is a key index to measure the beer quality, nutritional value, foam characteristics, wine taste and storage life. The traditional hydrometer method and volumetric bottle method for measuring beer density (relative density) have disadvantages such as low precision, long time, large sample consumption and easy to produce errors, which are difficult to meet the needs of high frequency and large quantity detection in modern beer production. With advanced technology, Shanghai Jiahang Instrument Co., Ltd. fully automatic density meter brings new solutions for density detection in the beer brewing industry.

Second, the importance of the concentration of the original beer wort and the measurement principle

The concentration of raw beer wort reflects the content of fermentable sugars before fermentation and is determined by the sugars converted from barley malt and auxiliary raw materials, such as 120 grams of sugars per liter of wort, the malt concentration is 12°. The higher the concentration, the higher the nutritional value of beer, the better the performance of foam, wine taste and shelf life.

According to GBT4928-2008 "Beer Analysis", the "true concentration" and "alcohol" of the sample should be measured by the relative density method, and the formula is as follows: (P(%)=(A * 2.0665 + n)/(100 + 1.0665 + A), (A is beer alcohol, n is the true concentration) can be converted to obtain the original wort concentration.

Application of Shanghai Jiahang automatic density meter

(1) Instrument advantages

Small sample size: Only 2-3 ml of sample is required to reduce sample loss, which is more advantageous for special or precious beer sample testing, while reducing operator exposure risk.

Rapid measurement: After the temperature balance, the measurement of a single sample only takes about 1 minute, which can quickly obtain the test results, adapt to the rapid detection needs of a large number of samples on the beer production line, and improve production efficiency.

Easy to operate and high precision: the operation interface design is simple and intuitive, and the operator can be skillfully operated by simple training. High-precision sensors and advanced measurement technology ensure high measurement accuracy and are suitable for frequent inspections during beer production.

Convenient data processing: equipped with a variety of communication interfaces, data can be saved, exported and printed. Measurement results are automatically saved, which facilitates subsequent data management and analysis, and also facilitates the generation of test reports.

(2) Measurement steps

Start preheating: turn on the automatic density instrument power source, wait for the internal temperature balance of the instrument after starting, to ensure the stability of the measurement environment, the general preheating time is short, can quickly enter the measurement preparation state.

Calibrating instrument: Start up for the first time or calibrate periodically. Use dry air and high purity water to calibrate according to the instrument operating guide. The calibration process is simple and fast, which can effectively ensure the measurement accuracy.

Injection operation: Use a supporting syringe to absorb 2-3ml beer sample and slowly inject it into the U-shaped quartz glass tube of the instrument to ensure that the sample is free of bubbles. If there are bubbles, gently tap the glass tube to discharge the bubbles and avoid affecting the measurement results.

Measurement start: After the sample temperature is balanced with the internal temperature of the instrument, select the beer density measurement mode on the instrument operation interface and start the measurement procedure. The instrument automatically completes the measurement and processes the data.

Data acquisition and processing: After the measurement, the instrument screen directly displays the measurement results, including beer density, alcohol conversion according to density and other relevant parameters. The measurement data can be automatically saved, exported to the computer through USB, RS232 interface, or stored directly using the U disk, which is convenient for subsequent analysis.

Cleaning and maintenance: After the measurement is completed, start the air pump with the instrument to discharge the sample, and then clean the U-tube with distilled water and anhydrous alcohol in turn to remove the residual sample. Finally, dry the U-tube with dry air to prevent the residual liquid from affecting the accuracy of the next measurement and extend the service life of the instrument.

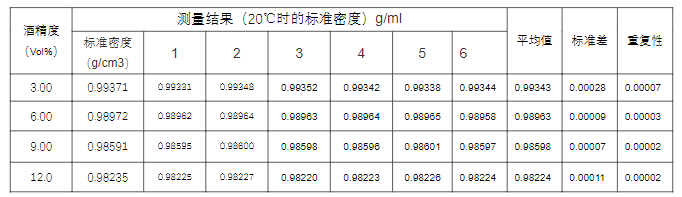

(3) Examples of measurement data

(Actual measurement data may vary according to instrument performance and measurement environment, the above data is only an example)

4. Factors affecting measurement and countermeasures

(1) Temperature influence

Temperature has significant influence on beer density and U-tube geometry. Shanghai Jiahang automatic density meter is equipped with high precision temperature control system, temperature control accuracy can reach [specific temperature control accuracy], can accurately control the measurement temperature, reduce the error caused by temperature fluctuations. Before measuring, ensure that the temperature of the instrument and sample is consistent and in the appropriate measuring range.

(2) The effect of bubbles

The air bubbles in beer will increase the resonant frequency and decrease the density. When the sample is injected, the sample is slowly absorbed in strict accordance with the operating specifications to avoid bubbles. If the sample is found to have bubbles, it can be measured after standing or tapping.

(3) The influence of pressure

Sample pressure affects U-tube deformation and sample density. The instrument design fully considers the pressure factor, and reduces the influence of pressure on measurement by optimizing the structure and material. Keep the sample pressure stable during measurement to avoid external pressure interference.

(4) Time impact

Beer is volatile and should be tested as soon as possible after injection. The operation process is skilled and fast, reducing the exposure time of the sample in the air, ensuring that the measurement results accurately reflect the real situation of the sample.

V. Conclusion

Shanghai Jiahang's fully automatic density meter has a significant advantage in the detection of raw wort concentration in the beer brewing industry. Its efficient, accurate and convenient measurement method can effectively meet the high frequency and large volume inspection needs in the beer production process, help enterprises to achieve accurate quality control, improve product quality, play an important role in the quality inspection link of the beer brewing industry, and promote the development and progress of the industry.

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

+86 15021993094

Follow Us:

Pharma Sources Insight July 2025

Pharma Sources Insight July 2025