Twelve years of qualification

Twelve years of qualification

Audited Supplier

Audited Supplier

In This Store

Category:API Equipment > Drying Equipment

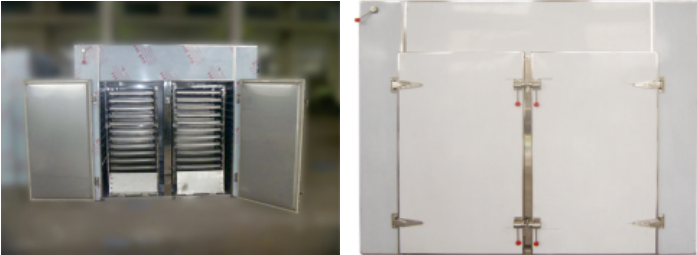

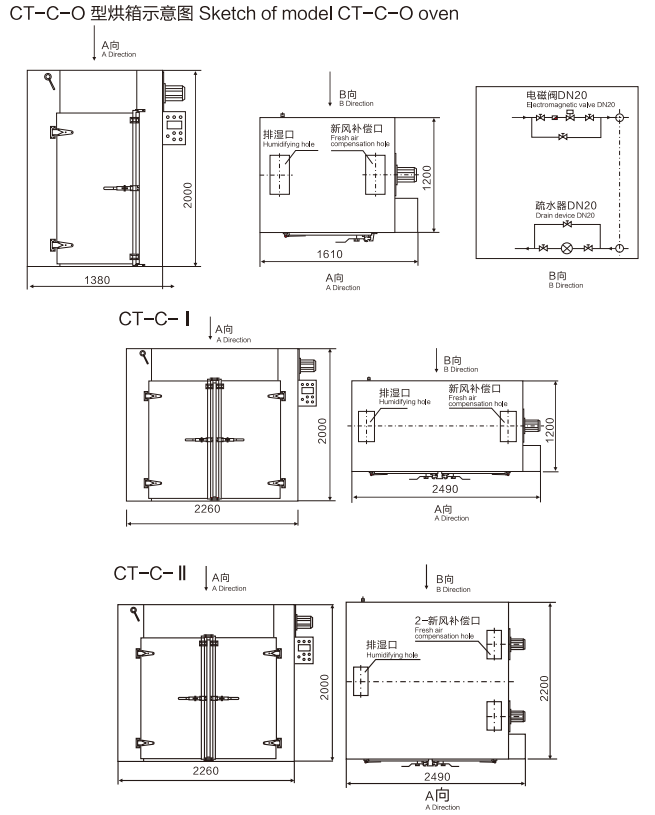

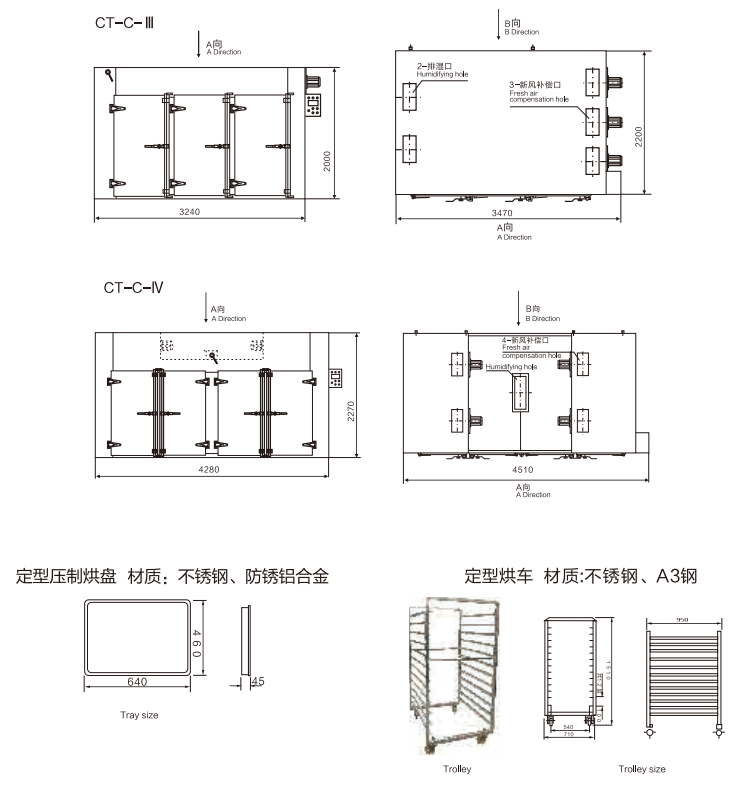

Product Name:CT-C TRAY DRYER

Price(USD):3000US$-20000US$

Company:Jiangyin Snynxn Granulating Drying Equipment Co.,Ltd

Factory Location: Jiangyin city,Jiangsu,China

Main Sales Markets: North America,Central/South America,Western Europe,Eastern Europe,Asia,Middle East,Africa

Monthly Production Capacity: 5

Contract Manufacturing: CMO

Packaging Information: Export wooden box

Delivery Lead Time: 2months

Sample Provided: no

Payment Terms: T/T

Descriptions

CT-C series hot air circulation drying oven uses a low noise and high temperature proof axial flow blower and an automatic temperature control system. The whole circulation system is the fully enclosed to make that the heat efficiency of the drying oven increases from 3〜7% of the traditional drying oven to 35-45% of the present one. The highest heat efficiency can reach 50%. The successful design of CT-C hot air circulation drying oven makes that the hot air circulation drying oven in our country catch the advanced level both at home and abroad. In order to save a large quantity of the energy in out country, in order to enhance the economic results of the enterprises, in 1990, the medicine management bureau of the State issued the industry standard and the uniform type is RXH.

1.Options of heat source: steam, electricity, or far infrared, or both steam electricity.

2.Drying temperature: steam heating 50-140℃,Max. 150℃ .

3.Electricity and far infrared:50-350℃. Automatic control system and computer control system on request.

4. There are automatic control system and computer control system for users' selection

5. Commonly used steam pressure 0.2-0.8Mpa(0.2-8 kg/cm2).

6. For CT-C-I,electric heated, rated power consumption: 15Kw, real consumption: 5-8Kw.

7. The special requirements should be indicated at the time of order.

8. Please consult as for any special requirements.

9. For operation temperature of over 140℃ or less than 60℃,please indicate when order..

10. The ovens and baking trays made by our factory are uniform in dimensions, and can be exchanged each other.

11.Tray dimensions:460*640*45mm.

Technical Parameter

Technical Parameter

| 序号 No. |

型号 Model |

行业标准 Field standard model | 技术参数 Technical parameter | 辅助设备accessory | 总重量 Total weight |

||||||||||

| 蒸发面积 Evaporate d area (m3) |

有效容积 Effective volume (m3) |

干燥量 Drying capacity (kg/batch) |

散热器面积 radiator area(m3) |

蒸汽耗量Steam consumption on(kg/h) | 电加热功率 Electrical Heater power(kw) |

风机风量 Fan volume (m3/h) | 风机功率 Fan power (kw) | 外形尺寸 Overall dimension W×D×H |

已配烘车(辆) Equipped drying cart(set) | 应配烘盘(只) Equipped drying tray (PC) |

温度自控箱 Temperature automatic control box |

||||

| 1 | CT-C-O | RXH-7-C | 7.1 | 1.3 | 60 | 15 | 15 | 6-9 | 4510 | 0.45 | 1380×1200×2000 | 1 | 24 | available | 820 |

| 2 | CT-C-I | R×H-14-C | 14.1 | 2.6 | 120 | 23 | 20 | 15 | 4510 | 0.45 | 2260×1200×2000 | 2 | 48 | available | 1580 |

| 3 | CT-C-II | R×H-27-C | 28.3 | 4.9 | 240 | 48 | 40 | 30 | 9020 | 0.45×2 | 2260×2200×2000 | 4 | 96 | available | 1800 |

| 4 | CT-C-IIA | R×H-27-C | 28.3 | 4.9 | 240 | 48 | 40 | 30 | 9020 | 0.45×2 | 4280^1200×2270 | 4 | 96 | available | 1880 |

| 5 | CT-C-III | R×H-41-C | 42.4 | 7.4 | 360 | 72 | 60 | 45 | 13530 | 0.45×3 | 2260×3200×2000 | 6 | 144 | available | 2100 |

| 6 | CT-C-IIIA | R×H-41-C | 42.4 | 7.4 | 360 | 72 | 60 | 45 | 13530 | 0.45×3 | 3240×2200×2000 | 6 | 144 | available | 2210 |

| 7 | CT-C-IV | R×H-54-C | 56.5 | 10.3 | 480 | 96 | 80 | 60 | 18040 | 0.45×4 | 4280×2200×2270 | 8 | 192 | available | 2800 |

| 8 | CT-I | R×H-14-B | 14.1 | 2.6 | 120 | 23 | 20 | 15 | 1414 | 1.1 | 2480×1200×2375 | 2 | 48 | none | 1220 |

| 9 | CT-II | R×H-27-B | 28.3 | 4.9 | 240 | 48 | 40 | 30 | 5230 | 1.1 | 2480×2200×2438 | 4 | 96 | none | 1530 |

| 10 | CT-III | R×H-41-B | 42.4 | 7.4 | 360 | 72 | 60 | 45 | 9800 | 2.2 | 3430×2200×2620 | 6 | 144 | none | 2110 |

| 11 | CT-IV | R×H-54-B | 56.5 | 10.3 | 480 | 96 | 80 | 60 | 9800 | 2.2 | 4460×2200×2620 | 8 | 192 | None | 2300 |

Features

♦ Most of hot air is circled inside the oven. The heat efficiency is high and the energy source can be saving.

♦ Using enhanced ventilation and adjustable air separating boards . It can make materials dried uniformly. The heat source can be steam, heat conductive oil, electricity or far infrared.

♦ The machine makes little noise and can be operated stably. The temperature can be controlled automatically and the installation and maintenance are all very convenient.

♦ With wide scope of application, it is suitable for drying varieties of materials. So it is a current type of drying equipment.

Applications

It is suitable for heating and solidificating, drying and dehydrting of raw materials in pharmaceutical industry,chemical industry, foodstuff industry, agricultural and sideline products, aquatic products, light industry and heavy industry such as raw material medicine,Chinese traditional medicines, tablet of drink, immersed electuary, powder, granule, packing bottle, pigment, dyestuff,dehydrated vegetables, dried fruit and melons, banger, plastic resin, electric elements, painting.

Flow chart

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

+86 15021993094

Follow Us:

Pharma Sources Insight January 2025

Pharma Sources Insight January 2025